Is your business required to reduce the risk of Legionnaires’ disease?

TME are specialist manufacturers of digital thermometers, probes and sensors used for the prevention of Legionnaires’ disease.

Read our advice on preventative water temperature testing, your legal obligations, and the equipment we recommend to help you manage the risk.

Legionnaires’ disease is a potentially fatal form of pneumonia. The cause of the disease is a bacterium called legionella pneumophila.

How is it caught?

Legionnaires’ disease is caught by inhaling small droplets of water suspended in the air which contain the legionella bacterium.

What are the sources of legionella bacterium?

The legionella bacterium is found naturally in ponds and rivers or in buildings containing cooling towers, evaporation condensers, air conditioning and industrial cooling systems, humidifiers, spa baths and hot and cold water systems.

Why is water temperature important?

Why is water temperature important?

Legionella bacterium multiplies in water at temperatures between 20-45ºC. So a well-established method of reducing risk is to maintain an effective water temperature testing regime.

Who is most at risk?

Risk increases with age and is also an issue for anyone with reduced immunity. People most at risk are people over 45, smokers and heavy drinkers, diabetics and people who are already ill – particularly with chronic diseases or whose immune system is impaired. This means that young children, the elderly, hospital patients and residents of care and nursing homes or assisted living establishments are also a potential risk.

Which buildings are most at risk?

A surprisingly wide range of buildings and work places: typically local authority residential accommodation, universities, hospitals, nursing and care homes, housing associations, charities, hostels, private landlords, managing agents, hoteliers and holiday accommodation providers. But many other buildings may be are affected; the first known outbreak of Legionnaires’ disease was traced to a hotel, with more recent incidents occurring in a restaurant air conditioning outlet, a school hot water system, rooftop water tanks in an office block and factory cooling towers. TME supplies legionella equipment to a diverse range of businesses – from accountancy firms to marinas.

Your Legal Responsibilities

All businesses – regardless of size or type – are required by law to undertake a risk assessment and then manage and maintain risk reduction procedures.

The Approved Code of Practice (ACOP) L8 issued by the Government’s Health and Safety Executive (HSE) recommends that hot water in a building should be stored above 60°C and distributed above 50°C (or 55°C for care homes and healthcare establishments), and cold water stored and sored below 20°C. Water outlets – especially sentinel points – must be routinely monitored to ensure safe temperatures.*

This code applies to all hot and cold water systems in the workplace regardless of their capacity (i.e. the lower limit of 300 litres previously used to exclude domestic systems no longer applies). Whilst domestic systems may represent a risk, the code only applies to risk arising at places of work or business premises.

This code applies to all hot and cold water systems in the workplace regardless of their capacity (i.e. the lower limit of 300 litres previously used to exclude domestic systems no longer applies). Whilst domestic systems may represent a risk, the code only applies to risk arising at places of work or business premises.

This means that all employers who manage premises with hot/cold water systems and/or wet cooling systems have a legal responsibility to identify any risk of contamination and to prevent or control it. The code requires that a risk assessment is carried out by a competent person in order to establish risk level and formulate any necessary control measures

* Care must be taken when water is kept and run hot, to ensure that measures are taken to prevent scalding.

TME’s Specialist Legionella Temperature Range

We have developed a dedicated range of temperature equipment to help speed up and simplify compliance with ACoP L8 water testing. All products are listed in the Legionella section of our website and are available to buy on line. Here is a summary of the main products we recommend followed by a table of parameters.

Thermometers

MM2008 Legionella Thermometer with Integral Water Temp TimerThis robust all-purpose thermometer features an in-built timer with 1 and 2 minute countdown buttons for running hot and cold water, designed to speed up and simplify timed running water tests on taps and showers. It is compatible with all TME probes and sensors. |

|

Probes

|

BSKS01-S Budget K type Dual Probe TS01-S T Type Dual Surface/Immersion Probe KS01-S K Type Dual Surface/Immersion Probe KS20-S K Type High Speed Dual Surface/Immersion Probe Dual purpose surface/immersion probes which can be used for both surface measurements on pipes and calorifiers as well as running water from taps and showers – eliminating the need to switch between different probes.

|

|

KS07 K Type High Temperature Surface Probe TS07 T Type High Temperature Surface Probe Separate handheld probes for surface measurements.

|

|

TM03 T Type General Purpose (MI) Probe KM03 K Type General Purpose (MI) Probe Separate handheld probes for running water or tank immersion.

|

|

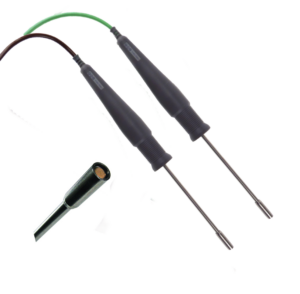

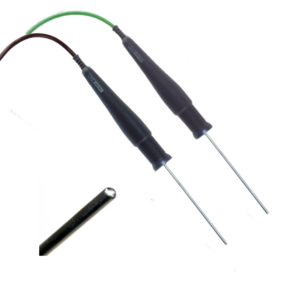

KA01 K Type PTFE Fine Wire Thermocouple TA01 T Type PTFE Fine Wire Thermocouple KM07 K Type Immersion Probe Fine wire thermocouple sensors which can be left in situ, available in different lengths.

|

Specifications

| Measurement Range °C | Accuracy @ 23°C | Battery | |

| MM2008 | -200 to 1372 | ±0.2°C ±0.15% of reading | PP3 |

| Temperature Range °C | Probe Dimensions (mm) | Fitted/Suppled With | |

| BSKS01-S | -50 to +300 | 110 x 10 | 1m Straight Cable and minature plug |

| KA01 | -100 to +250 | 1 m PTFE insulation 0.3 diameter wire | Miniature plug |

| KS01-S | -50 to 250 | 110 x 10 | 2m Curly Cable and miniature plug |

| KS07 | -50 to 600 | 110 x 6 | 2m Curly Cable and miniature plug |

| KS20-S | -50 to 250 | 115 x 12 | 2m Curly Cable and miniature plug |

| TA01 | -100 to +250 | 1 m PTFE insulation 0.3 diameter wire | Miniature plug |

| TM03 | -50 to +400 | 100 x 3 | 2m Curly Cable and miniature plug |

| TS01-S | -50 to 250 | 110 x 10 | 2m Curly Cable and miniature plug |

| TS07 | -50 to +400 | 110 x 8.5 | 2m Curly Cable and miniature plug |

| KM03 | -200 to 1100 | 100 x 3.5 | 2m Curly Cable and miniature plug |

| KM07 | -50 to 250 | 50 x 4 | 2m PTFE insulated and miniature plug |

Kits

TME’s Legionnaires Temperature Kits feature the most popular, money-saving combinations of thermometers and probes, often including a carry case and log book.

| Product | CLEGK1 | CLEGK2 | CLEGK3 | LEGK1 | LEGK4 | LEGK5 | LEGK6 |

| MM2008 | X | X | X | X | X | X | X |

| BSKS01-S | X | ||||||

| KA01 | X | X | |||||

| KM03 | X | ||||||

| KS01-S | X | ||||||

| KS07 | X | ||||||

| KS20-S | X | ||||||

| TA01 | X | X | |||||

| TM03 | X | ||||||

| TS01-S | X | ||||||

| TS07 | X | ||||||

| TEMPRB | X | X | X | X | |||

| CASE | X | X | X | X | |||

| POUCH | X | X | X |

TME kits may be used to monitor the temperature of running water from taps and showers, surfaces of pipes calorifiers and standing water in tanks.

How to take a temperature measurement for legionella testing

Taking temperature of running water

• Run the tap for the prescribed time;

• Place the end of the immersion probe (or surface/immersion probe if you are using a dual purpose probe) in the water flow making sure the last 10mm is immersed

• Plug in your thermometer;

• Once the reading on your thermometer has stabilized you can record the temperature;

Please note that if a TMV is fitted, you will need to take the surface temperature of the hot water pipe before it enters the valve.

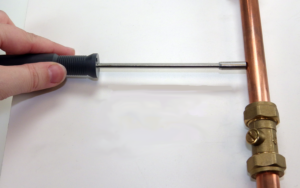

Taking temperature of water pipe surfaces

Taking temperature of water pipe surfaces

• Choose a smooth area of pipe for a more accurate result;

• Using very light pressure, apply the tip of the surface probe (or surface/immersion probe if you are using a dual purpose probe) to the pipe;

• Keep the probe still and avoid rotation to extend the life of your probe;

• Plug in your thermometer;

• Once the reading on your thermometer has stabilized you can record the temperature;

Please note that surface probes are designed for use on smooth, even surfaces. Undue pressure or movement of the probe tip whilst in contact with the measurement surface may result in irreparable damage to the sensor.

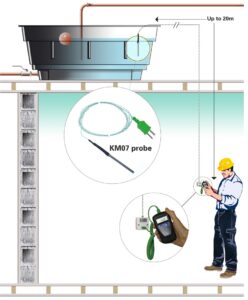

Taking temperature of water in a tank

• Place a fine wire thermocouple sensor (or a KM07 immersion probe if preferred) in the water to a minimum depth of 20 mm;

• Plug in your thermometer;

• Once the reading on your thermometer has stabilized you can record the temperature;

Please note that the sensor/probe can be left in situ until the next test (also see instructions below for use with a TC Wall Port).

Specialist Solution for temperature points with difficult access

If you have temperature points that are hard to reach, consider using TME’s TCWALLPORT System, designed for boxed in TMVs, awkwardly situated calorifier feed and return pipes and high-level water storage tanks.

If you have temperature points that are hard to reach, consider using TME’s TCWALLPORT System, designed for boxed in TMVs, awkwardly situated calorifier feed and return pipes and high-level water storage tanks.

The TCWALLPORT is a low-cost, wall-mounted thermocouple monitoring point which is small, unobtrusive and easy to install. It is primarily designed for use with a fine wire thermocouple sensor KA01/TA01 which is permanently attached to the temperature test point and left in situ. The wire is then run to the port which can be sited in a more convenient position up to 20 metres away, avoiding the need to dismantle panels or work at height. The temperature is read by simply plugging a handheld thermometer into the port.

The system can also be used with the KM07 immersion probe.

Combined with a high accuracy thermometer like the MM2008, this system produces an instant temperature reading from up to 20 meters away with no loss of accuracy.

TCWallport System Products

TCWallport Thermocouple Temperature Monitoring Point (white)

TCWallportR Thermocouple Temperature Monitoring Point (Red – for Hot Water)

TCWallportB Thermocouple Temperature Monitoring Point (Blue – for Cold Water)

KA01 K Type Fine Wire Thermocouple Probe 1m x 0.3mm

TA01 T Type Fine Wire Thermocouple Probe 1m x 0.3mm

The KA01 and TA01 fine wires are both also available in lengths of 3m, 5m, 10m and 20m

KMPC1MP K Type Thermocouple Connection Cable

TMPC1MP T Type Thermocouple Connection Cable

The above leads are also available in 2 meter lengths

Please note a Connection Cable is needed to connect thermometer to the wallport

Specialist Solution for paperless recording using barcodes

Paperless recording of temperature tests provides ultimate peace of mind, being less vulnerable to human error.

Paperless recording of temperature tests provides ultimate peace of mind, being less vulnerable to human error.

Traceable records are a vital part of any water temperature compliance procedure. Barcode technology offers an effective method of guaranteeing these records. Barcodes can be displayed on any test point, they’re easy and free to generate to your own specifications and they can identify test points instantly.

TME’s range of MM7000 Barcode reading thermometers record time, date and temperature of each test point, together with its unique

location. Achieve paperless records by downloading readings via Bluetooth or USB to PC, smartphone or tablet. You can also programme alarms which display warning outside of set temperature parameters. Export to a spreadsheet to generate digital temperature logbooks.

All TME probes and sensors are compatible.

Additional Advice

Other water treatment methods

These include the use of biocides, ultra violet (UV) irradiation, copper/silver inonisation, ozone and chlorine dioxide. Information about these methods is available from the Health & Safety Executive (HSE)

Reference documents *

(available from www.hse.gov.uk)

• Health and Safety Executive/Local Authorities Enforcement Liaison Committee (HELA) Local Authority Circular (OC 255/11)

• Legionnaires’ disease – A guide for Employers (HSE)

• Legionnaires’ disease – essential information for providers of residential accommodation (HSE)

*Whilst this information has been compiled using the reference documents above, it should not be used as sole guidance for the prevention of the spread of legionella bacterium. It is only intended to form part of a wider risk assessment and prevention/control strategy.

For more information on Legionella Temperature Monitoring, contact the TME Sales Team at sales@tmethermometers.com +44 (0)1903 700651

Cart